Sensor problems due to contamination

Many modern cars no longer have an oil dipstick, which is replaced by an oil level sensor that, together with the oil pressure sensor, monitors the engine oil. Contamination of the oil system can cause the sensors to malfunction and give incorrect values. A blockage in the oil pressure sensor causes the warning light to switch on and off even when there is plenty of oil and the oil pressure is high enough. Clean sensors are therefore necessary to guarantee proper working operation.

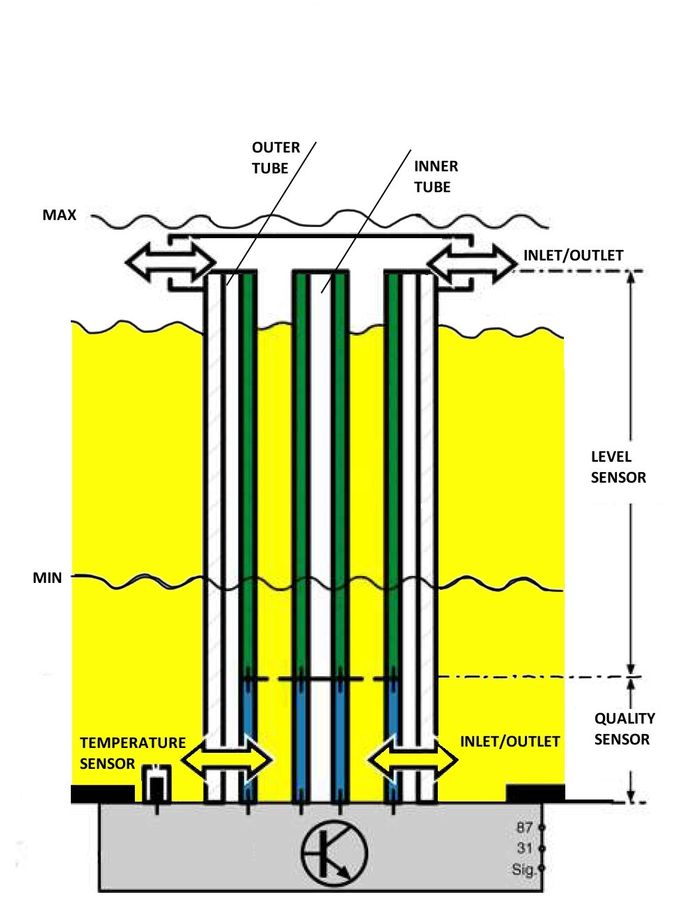

Working principle of the capacitive sensor:

The sensor consists of two cylindrical capacitors and is mounted in the oil sump at the bottom of the engine. The condition of the oil (pollution, aging) is measured by the lower capacitor (blue). The engine oil level is measured in the upper part of the sensor (green). The oil level, oil temperature and oil condition are measured continuously.

The oil (yellow) is located between the electrodes as a dielectric. The specific resistance of motor oil changes with increasing carbon particles and metal splinters. This change in the dielectric changes the capacitance of the lower capacitor. The signal indicates the level and aging of the engine oil.

When the oil level drops, the capacitance of the upper capacitor also changes.

These sensor values are processed in the engine management system to calculate the next oil change interval, and the level of oil in the sump.

The temperature sensor (NTC) is mounted at the base of the oil condition sensor to measure the oil temperature.

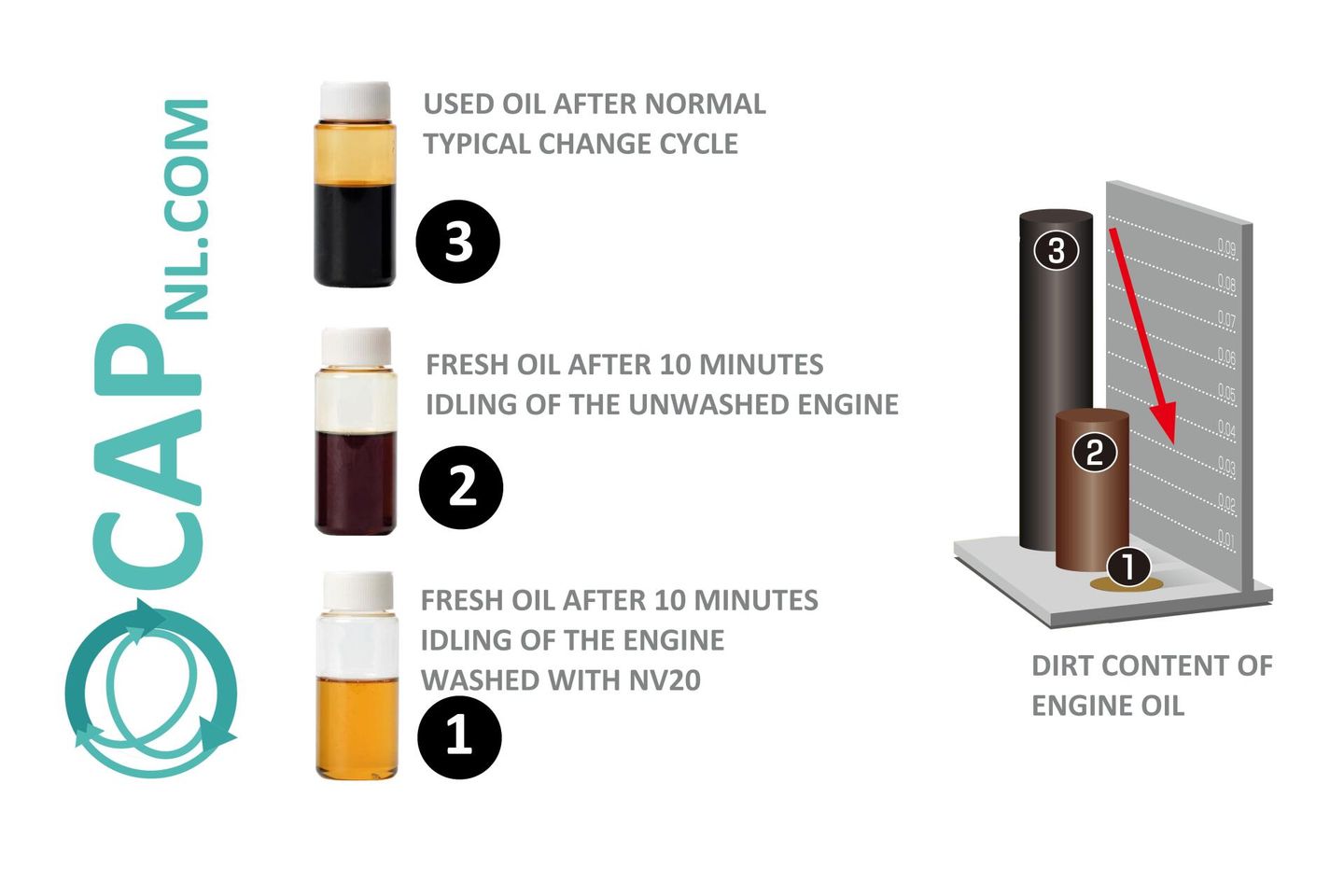

To some extent, all these problems can be prevented by changing the oil in time, but a large part of the contaminated oil always remains and the contamination that has already settled will not be removed. The Engine Washing Machine can be used to solve this problem. The NVS is connected to the filter housing and carter pan after the oil has been drained and the oil filter has been removed. In a cycle of only 12 minutes, cleaning fluid, a mixture of air/cleaning fluid and air is alternately pumped/blown through the motor. Thanks to this method, all places where oil normally comes are thoroughly cleaned. Finally, the engine is blown through with air so that any remaining liquid is discharged to the sump pan where it is extracted by the machine. Due to this thorough cleaning, the oil system is completely clean and the new oil can perform optimally again.

The big advantage of this cleaning method is that the engine does not have to run during cleaning and is easy to fit during a regular oil change. The total time needed for the engine wash is only a 12 minutes job!