Pollution of the Engine

A dirty engine loses power, has a higher fuel consumption and can cause permanent damage to the engine.

If an engine is not given the opportunity to reach the correct operating temperature, what is known as incomplete combustion, occurs. This results in carbon deposits in the engine which will strongly pollute the oil.

In cars that drive few kilometres, or often drive short distances, we regularly see that oxidation of the oil occurs, which gives the chance of contamination to settle in the engine.

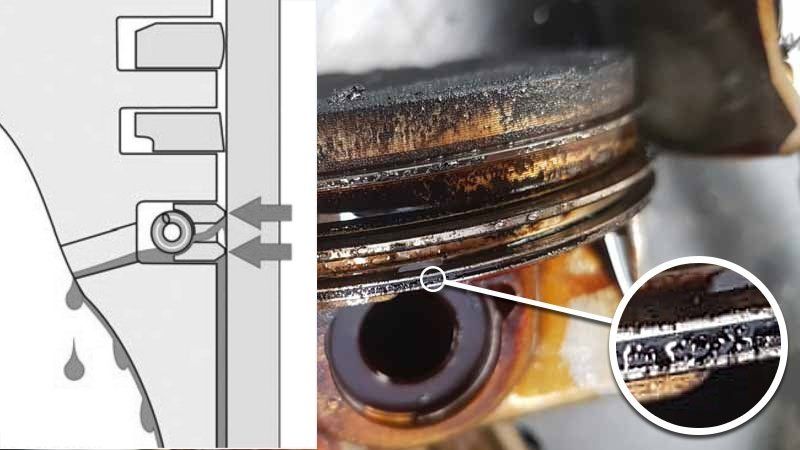

Contamination of oil scraper rings

In modern cars (with for example EURO6 engines) there is another problem. In these economical engines, the oil scraper rings are made as thin as possible. This minimizes friction between the piston and cylinder wall and the engine will use less fuel.

However, the disadvantage here is that the holes to drain the oil also get smaller and smaller. Dirty oil causes these drain holes to clog up.

Clogged oil scraper rings lead to increasingly higher oil consumption (1 litre per 1500 km is no longer an exception at a certain point). Such blockage of the oil scraper rings also leads to accelerated contamination of the engine and a higher oil & fuel consumption. More oil is entering the fuel chamber; resulting in incomplete combustion.

In particular 1.4, 1.8, 2.0 and 3.0 T (F) SI engines produced between 2008 and 2016 have this problem.

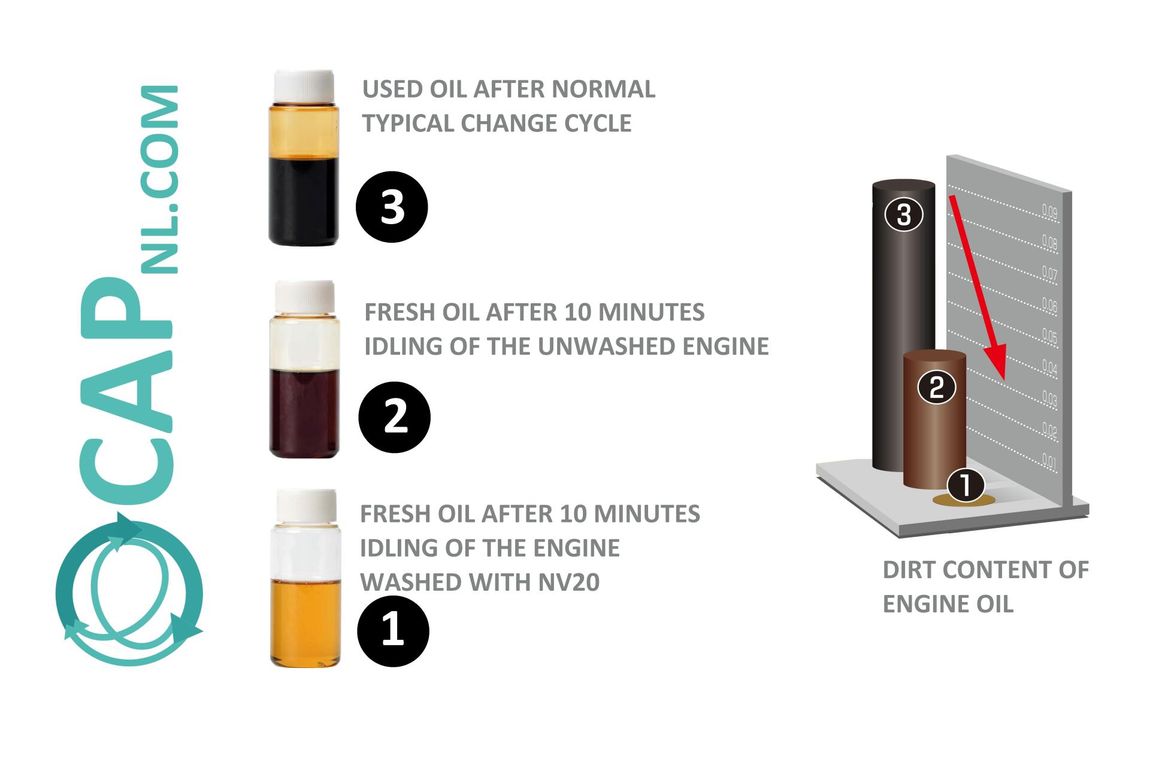

To some extent, all these problems can be prevented by changing the oil in time, but a large part of the contaminated oil always remains and the contamination that has already settled is not removed. The Engine Washing Machine can be used to solve this problem. The NVS is connected to the filter housing and carter pan after the oil has been drained and the oil filter has been removed. In a cycle of only 12 minutes, cleaning fluid, a mixture of air/cleaning fluid and air is alternately pumped/blown through the motor. Thanks to this method, all places where oil normally comes are thoroughly cleaned. Finally, the engine is blown through with air so that any remaining liquid is discharged to the sump pan where it is extracted by the machine. Due to this thorough cleaning, the oil system is completely clean and the new oil can perform optimally again. (see figure 6)

The big advantage of this cleaning method is that the engine does not have to run during cleaning and is easy to apply during a regular oil change.